Key Takeaways

- Revolutionizing Construction: Construction robotics enhances efficiency and precision while reducing labor costs, addressing industry challenges like safety and productivity.

- Diverse Applications: Robots such as autonomous vehicles and robotic arms perform specific tasks, improving workflow and reducing human error on job sites.

- Significant Benefits: The integration of robotics leads to increased efficiency and improved safety, with robots handling hazardous tasks and optimizing processes.

- Challenges in Adoption: High initial costs and workforce adaptation are key hurdles for companies looking to implement construction robotics, necessitating investment in training and technology.

- Future Innovations: Advancements in AI and machine learning are shaping the future of construction robotics, enabling real-time decision-making and enhanced precision.

- Sustainability Focus: Robotics contribute to eco-friendly practices in construction by reducing waste, promoting recycling, and optimizing energy efficiency.

Construction robotics is revolutionizing the way buildings are designed and constructed. With advancements in technology, robots are stepping onto job sites, enhancing efficiency and precision while reducing labor costs. These innovations not only streamline processes but also tackle the industry’s long-standing challenges, such as safety and productivity.

As the construction sector embraces automation, the integration of robotics is becoming increasingly vital. From bricklaying machines to drones surveying sites, these tools are reshaping traditional methods and paving the way for smarter construction practices. The future of construction looks promising, with robotics playing a crucial role in creating safer and more sustainable environments.

Construction Robotics

Construction robotics represent a significant innovation in the building industry, providing solutions that enhance efficiency, accuracy, and safety. These robotic technologies streamline tasks and transform traditional construction processes.

Definition And Purpose

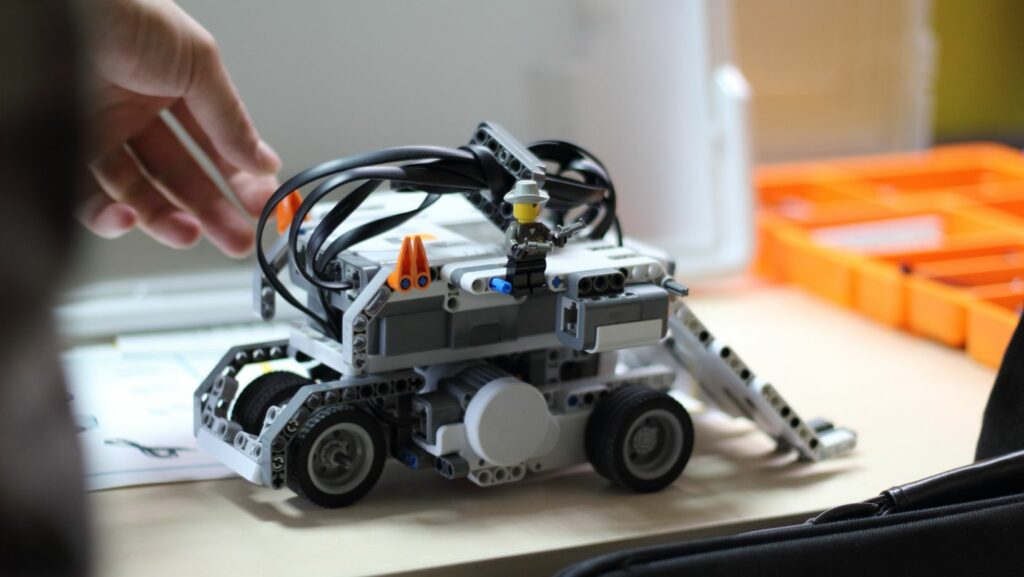

Construction robotics refers to automated machines designed for various tasks within the construction sector. These robots aim to improve project timelines, ensure precision in repetitive tasks, and enhance worker safety. Examples include autonomous vehicles for material transportation and robotic arms for tasks such as welding and assembly. Their purpose lies in reducing labor costs and addressing skill shortages while increasing overall productivity in construction projects.

Evolution Of Construction Robotics

The evolution of construction robotics traces back to the early 20th century, starting with simple mechanized tools. Over the decades, advancements in technology fostered the development of more sophisticated robots. In the 1980s, robotic arms began performing tasks in factories, marking a shift toward automation. The introduction of drones in the 2000s enabled aerial surveys and inspections, further advancing the field. Today, construction robotics integrates artificial intelligence and machine learning, allowing for adaptability on diverse job sites. The ongoing integration of these technologies promises continued advancements in construction methodologies and significant improvements in project delivery.

Types Of Construction Robots

Construction robots come in various forms, each designed to perform specific tasks efficiently. Below are key types of construction robots that contribute to enhanced productivity and safety on job sites.

Autonomous Vehicles

Autonomous vehicles play a significant role in material transportation on construction sites. These vehicles navigate job sites without human intervention, utilizing sensors, cameras, and GPS for precise movement. They transport materials, including concrete and steel, reducing the reliance on manual labor and increasing job site efficiency. For example, some autonomous trucks can haul loads of up to 20 tons while navigating complex terrains, ensuring timely deliveries and streamlining workflows.

Autonomous vehicles play a significant role in material transportation on construction sites. These vehicles navigate job sites without human intervention, utilizing sensors, cameras, and GPS for precise movement. They transport materials, including concrete and steel, reducing the reliance on manual labor and increasing job site efficiency. For example, some autonomous trucks can haul loads of up to 20 tons while navigating complex terrains, ensuring timely deliveries and streamlining workflows.

Robotic Arms

Robotic arms are versatile machines designed for precision tasks such as welding, assembly, and masonry. These robots can perform repetitive tasks with high accuracy, minimizing human error and improving overall work quality. Equipped with advanced sensors and AI, robotic arms adapt to various materials and project specifications. For instance, robotic arms can assemble building components with an accuracy rate of up to 98%, significantly enhancing construction speed and reducing rework.

Benefits Of Construction Robotics

Construction robotics significantly enhance the building process by improving efficiency and safety on job sites. These technological advancements offer numerous advantages that transform traditional practices.

Increased Efficiency

Increased efficiency defines the primary benefit of construction robotics. Robotics can perform repetitive tasks quickly and accurately, minimizing delays. For instance, autonomous vehicles operate continuously, transporting materials like concrete and steel between locations without rest, leading to faster project timelines. Robotic arms execute precision tasks, such as welding and assembly, with remarkable accuracy, reducing the likelihood of human error. Integration of data analytics further optimizes workflows, enabling real-time adjustments that enhance productivity levels.

Improved Safety

Improved safety represents another essential advantage of construction robotics. Robots take on hazardous tasks that pose risks to human workers, such as working at heights or handling heavy materials. This shift reduces the likelihood of workplace injuries and accidents. Automation also allows for safer working environments by minimizing human presence in danger zones. With features like real-time monitoring and advanced sensors, construction robots can detect potential hazards, ensuring proactive safety measures are in place. Overall, this technological evolution creates a culture of safety within the construction industry.

Challenges In Implementing Construction Robotics

Implementing construction robotics presents several challenges that can hinder their widespread adoption in the industry. Understanding these challenges is crucial for stakeholders aiming to integrate robotic solutions into their operations.

High Initial Costs

High initial costs represent a significant barrier for many construction firms. Investment in robotics involves purchasing advanced machinery, software, and ongoing maintenance, often resulting in expenses that some companies can’t justify. Robotics systems can range from tens of thousands to several million dollars, depending on the technology and its capabilities. Additionally, firms must consider the costs of training staff to operate and maintain these advanced systems. Without a clear return on investment, many companies hesitate to adopt these technologies, limiting the growth of robotics in the construction sector.

Workforce Adaptation

Workforce adaptation poses another challenge in implementing construction robotics. Construction workers may face difficulties in adjusting to new technologies that replace or supplement their roles. Resistance to change can arise from fears of job displacement or from a lack of familiarity with robotic systems. Companies must invest in training and skill development programs to facilitate the transition. Effective communication about the benefits of robotics—such as enhanced safety and reduced physical strain on workers—is essential to foster acceptance. Addressing these workforce adaptation issues ensures a smoother integration of robotics into construction practices.

Future Trends In Construction Robotics

Rapid advancements in technology continuously shape the future of construction robotics, driving innovations that enhance productivity and sustainability in the industry. Two key trends stand out: the integration of artificial intelligence (AI) and machine learning, along with the adoption of sustainable building practices.

AI And Machine Learning Integration

AI and machine learning increasingly play pivotal roles in construction robotics. Robots equipped with AI algorithms can analyze vast amounts of data to make real-time decisions, predicting potential issues before they arise. For example, robotic systems can adjust construction schedules based on weather data or project progress, ensuring optimal workflow. Machine learning enhances robots’ learning capabilities, allowing them to improve performance over time through experience. This technology not only boosts efficiency but also enhances precision, as robots can adapt to complex tasks and dynamic environments with greater accuracy.

AI and machine learning increasingly play pivotal roles in construction robotics. Robots equipped with AI algorithms can analyze vast amounts of data to make real-time decisions, predicting potential issues before they arise. For example, robotic systems can adjust construction schedules based on weather data or project progress, ensuring optimal workflow. Machine learning enhances robots’ learning capabilities, allowing them to improve performance over time through experience. This technology not only boosts efficiency but also enhances precision, as robots can adapt to complex tasks and dynamic environments with greater accuracy.

Sustainable Building Practices

Sustainability is a growing concern within the construction industry, and robotics contribute significantly to eco-friendly practices. Robots can facilitate precise measurements and materials usage, reducing waste during construction. Moreover, automated systems can utilize recycled materials directly on-site, promoting a circular economy. Innovations in construction robotics support efforts to reduce energy consumption, from automated equipment that optimizes energy use to drones that assess energy efficiency in buildings. This shift towards sustainable practices aligns with global environmental goals, positioning robotics as essential components in the future of construction.

AI in Building Industry

The rise of construction robotics marks a pivotal shift in the building industry. As these technologies evolve they promise to enhance efficiency and safety while addressing critical challenges like skill shortages. The integration of AI and machine learning not only streamlines workflows but also supports sustainable practices that align with global environmental goals.

Embracing construction robotics can lead to significant improvements in project timelines and accuracy. As firms navigate the initial costs and workforce adaptation, the long-term benefits will likely outweigh the challenges. The future of construction is bright with robotics at its core, paving the way for smarter and safer building practices.